End fineness: 90% < 2 mm

Very powerful

Infinitely reproducible gap adjustment

Easy change of jaw plates and side liner

Various infeed hoppers: removable, with safety guard, batch loader, and metering

External control by start/stop

Contamination-free grinding

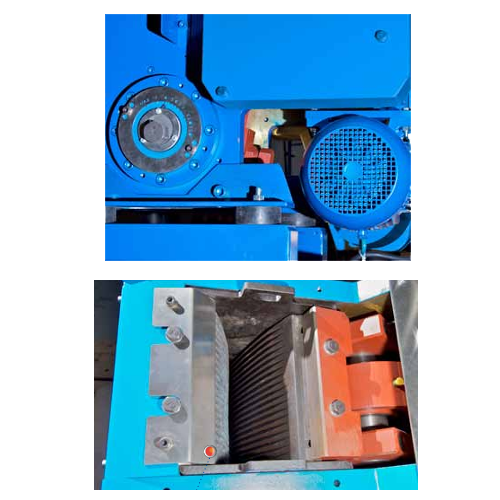

The Model LMFC 250 Jaw Crusher is used by labo- ratories and processing companies to crush solid materials such as rocks or soil and ores. The material to be processed falls into the crushing chamber of the LMC Crusher via a guide chute and is crushed by crushing action of a static and a dynamic jaw plate until it passes the pre-selected gap of the crusher.

The LAARMANN Fine Jaw Crusher is suitable for smalll amounts and can be used batch wise or for larger quantities continiously. Moveable and fixed jaw plate as well as the side liner can be easily replaced

Improved power by 7500 Watt (3-phase motor)

Optimal grinding results by oscillating grinding movement

Adjustable gap adjustment

CE-certified

Removable infeed hopper with safety guard or batch loader

Base

Spacious collector

External control by start/stop

End fineness: < 2.00 mm

Contamination-free grinding with 4 different grinding tools

Easy exchange of jaw plates and side liners

Unlike conventional jaw crusher, the movable crushing jaw is guided in this jaw breakers in an oscillating motion. As a result the crushing gap remains in the downward direction in the adjusted size and the product is crushed in a single step in this fineness.

The requested gap setting can be adjusted comfortably and reproducibly.

Will our equipment suit your requirements? Send us a test sample for evaluation. Our application laboratory is pleased to conduct pre-purchase trials on customer free supplied samples.

If you require a test-grinding please click the Questionnaire Milling button and fill out the form.

| Jaw Inlet | 130mm x 250mm |

| Adjusting range of Jaw outlet | 0 – 5 mm |

| Dimensions W x D x H | 899 x 565 x 795 mm |

| Approximate mass | 880 kg |

| Dust extraction flow | 225 liter/s |

| Dust extraction point | 2 |

| Electrical requirements (3 phase) | 7,5 KW, 3-phase 50Hz |

| End-fineness | 90% < 2 mm |

| Max | < 110mm |

| Throughput | 500 kg/h |

| Toggle speed | 775 rpm |

| Material of grinding tools | Manganese steel, Tungsten carbide, Hardened steel, Heavy metal poor steel, Stainless steel or others on request |

| Collector capacity | 9L higher volume on request |